Integrated Biocatalysis Services

Transform Your Chemical Pathways with Advanced Biocatalysis Solutions

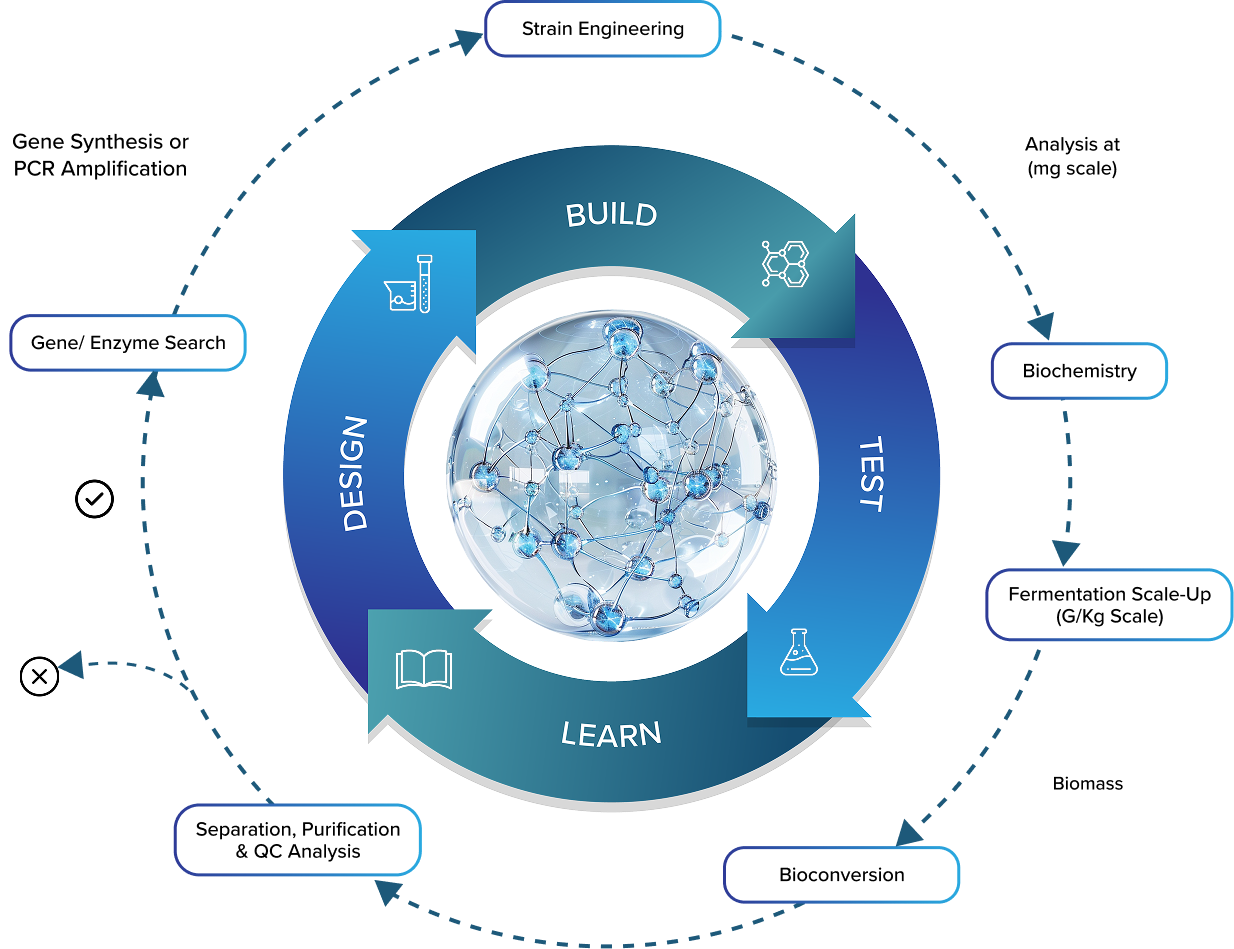

At PI Health Sciences, through our Center of Excellence in Biotechnology and Biocatalysis, we provide end-to-end Biocatalysis Services spanning gene discovery, enzyme development, strain engineering, and large-scale bioprocess production. Backed by state-of-the-art biotechnology laboratories and deep scientific expertise, we enable industries to achieve higher yields, superior purity, and eco-efficient manufacturing processes.

Our comprehensive biocatalysis solutions are designed to accelerate development timelines while ensuring precision, scalability, and sustainability. By leveraging in-house strain engineering, enzymatic transformation, and advanced bioprocess platforms, we deliver customized biocatalytic solutions tailored to complex chemical and biological challenges. We integrate whole-cell and cell-free biocatalysis, custom enzyme and strain engineering, and green chemistry principles to transform conventional chemical pathways into efficient, low-impact processes. This approach enhances process robustness, reduces waste, and minimizes environmental footprint—making our services ideal for pharmaceutical and specialty chemical manufacturing.

With agile execution models, transparent collaboration, and data-driven decision-making, PI Health Sciences supports scalable and sustainable biocatalytic manufacturing from early development to commercial production.

| Enzyme Type | Supplier | Kit Size |

|---|---|---|

| Transaminase | 24 Enzymes | |

| Keto-Reductase | Codexis | 24 Enzyme |

| Ene-Reductase | 8 Enzymes | |

| Nitro Reductases | Syncozymes | 12 Enzymes |

| Amidation enzymes (Acyltransferases) |

| Enzyme Type | Kit Size |

|---|---|

| Transaminase | 15 |

| Keto-Reductase | – |

| Ene-Reductase | 10 |

| Nitro Reductases | 22 |

| Amidation enzymes (Acyltransferases) |

– |

Our Capabilities

Gene-to-Process Biocatalysis Workflow

Single, continuous execution from gene identification through enzyme expression, bioconversion, and process definition, enabling faster transition from concept to executable manufacturing routes.

Targeted Enzyme and Strain Design

Rational enzyme selection and strain engineering focused on activity, selectivity, and stability, aligned to the specific chemistry and process constraints of each program.

Rapid Screening and Decision Acceleration

High-throughput screening combined with fast analytical validation to eliminate low-value candidates early and focus development on the most viable biocatalysts.

Whole-Cell and Cell-Free System Optimization

Parallel evaluation and deployment of whole-cell and isolated enzyme systems to maximize conversion efficiency, robustness, and scalability.

Gene-to-Process Biocatalysis Workflow

Controlled fermentation and biotransformation capabilities from mL to 200 L, designed for smooth scale-up to G and Kg-level outputs without process re-engineering.

Sustainable Process Integration

Biocatalytic routes engineered to reduce solvent use, energy input, and waste generation, supporting greener, regulator-aligned manufacturing outcomes.

Frequently asked questions

We’re here to help with any questions you have about our plans, supported features, and how our model works.

What types of projects are best suited for biocatalysis at PI Health Sciences?

Our biocatalysis services are ideal for complex chemical transformations where selectivity, yield, or sustainability are critical. We support pharmaceutical and specialty chemical programs requiring enzyme discovery, strain development, or scalable bioconversion solutions.

How do you choose between whole-cell and cell-free biocatalysis approaches?

The choice is driven by process efficiency, stability, and cost considerations. We evaluate substrate complexity, reaction conditions, and scale requirements to select the approach that delivers the best technical and economic outcome.

Can you support scale-up from early discovery to manufacturing volumes?

Yes. Our infrastructure supports seamless progression from mg-scale screening to G and Kg-scale fermentation. Processes are designed with scalability in mind from the outset, ensuring consistency as programs move toward production.

How does biocatalysis improve sustainability compared to traditional chemistry?

Insights & Resources

Experience case studies from around the services

Contact Us

Unlock the full potential of Biocatalysis with PI Health Sciences.

Get in touch with our experts today to explore enzyme engineering, strain development, and bioconversion solutions designed to transform your manufacturing processes.