Manufacturing Services and Solutions

Home  Solutions

Solutions  Manufacturing

Manufacturing

Manufacturing Services and Solutions

Home  Solutions

Solutions  Manufacturing

Manufacturing

Manufacturing Services and Solutions

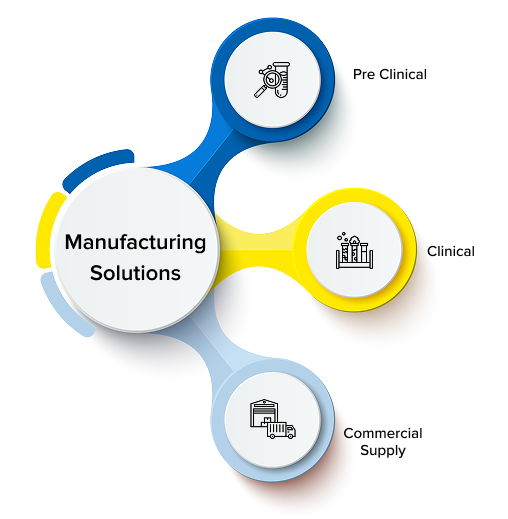

At PI Health Sciences, we provide end-to-end pharmaceutical manufacturing services that support your drug development journey from early-stage research to commercial-scale production. Our cutting-edge infrastructure is built to ensure phase-appropriate supply for clinical candidates, backed by a global manufacturing network that includes starting materials, intermediates, and drug substances.

Our innovative approach includes lifecycle management of APIs, where our R&D team excels in designing cost-effective, scalable, and high-yield routes. These advancements not only drive efficiency in pharmaceutical manufacturing but also help make life-saving products more accessible to patients. We also offer an integrated, one-stop solution for high-potency API (HPAPI) development—from early discovery to commercial supply—ensuring a seamless experience in pharma drug manufacturing.

Global Manufacturing Capabilities

Jaipur, Rajasthan

Our Jaipur facility specializes in process development, scale-up, and manufacturing of preclinical materials and intermediates, forming a key part of our pharmaceutical manufacturing services portfolio.

- Pilot Plant: 50–200 L reactors (GLR, SS)

- Plant Reactors: 50–5,000 L

- Operating Conditions: -60°C to +160°C, 10 mbar to 6 bar

- Certifications: ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, OHSAS 18001:2007

Lodi, Milan

Our Lodi site is a global hub for regulatory starting materials and drug substances, supporting large-scale pharma drug manufacturing operations.

- Reactor Range: 50–10,000 L

- Conditions: -20°C to +160°C, 10 mbar to 6 bar

- Specialties: Multi-Purpose APIs (170 m³), Large-Volume Products (50 m³), Anti-cancer Products (30 m³)

Our Expert Team

At PI Health Sciences, our pharmaceutical manufacturing services are led by a world-class team of chemists, engineers, and quality experts. Their deep domain knowledge ensures that each project is executed with strategic foresight, technical precision, and compliance with global regulatory standards.

This multidisciplinary approach helps us respond swiftly to changing industry needs and deliver top-tier results in both pharmaceutical manufacturing and pharma drug manufacturing environments.

Our Expert Team

At PI Health Sciences, our pharmaceutical manufacturing services are led by a world-class team of chemists, engineers, and quality experts. Their deep domain knowledge ensures that each project is executed with strategic foresight, technical precision, and compliance with global regulatory standards.

This multidisciplinary approach helps us respond swiftly to changing industry needs and deliver top-tier results in both pharmaceutical manufacturing and pharma drug manufacturing environments.

Contact Us

Let’s work together. Connect with us today to explore how our customized pharmaceutical manufacturing services can power your next innovation in pharma drug manufacturing.